In the last post I started covering the installation of the glass scales on my Grizzly G0463 (AKA Sieg X3) mill. You might recall that I got the scales loosely mounted on the mill but didn’t have a controller to use them with. I didn’t want to tie-up the unit I’ve been using for testing, so before going any further I had to build a new one. This weekend I got some free time to finally build the controller and [mostly] button thing up.

Blog dedicated to a DIY digital readout project and other hobby machining subjects

Adding DRO to my Grizzly G0463 (Sieg X3 Mill)

Sunday, December 8, 2013Several people asked me to post pictures of my DRO setup. Today I started installing a new DRO unit on my Grizzly G0463 (A.K.A. Grizzly Small Mill/Drill or Sieg X3) mill and decided to take advantage of this opportunity to take some pictures and post the progress.

I’ve been itching to get a set of glass DRO scales for a while but the cost has kept me off. Last July I randomly emailed a seller on eBay and asked if they would happen to have a returned or blemished unit they’d sell to me for experimenting. Surprisingly the guy replied that he is discontinuing the Easson scales and has two units [8” and 16”] that he’d sell at a steep discount. Additionally, he had one with a broken reading head that he’d throw in if I wanted it for parts. He wanted $200 for all three of the scales, including shipping. Needless to say, I jumped at the opportunity. When the scales came, I took the broken unit apart to see what’s inside and right off the bat found the problem. The Vcc line was broken and the exposed wire was shorting to the case. Five minutes later I had three working scales: one 8” long, and two 16”.

Selecting Scales for a DRO

Friday, December 6, 2013When building a DRO the selection of scales is the most critical decision. Touch DRO Android application can work with a number of different scale types, ranging from inexpensive calipers to 1 micron glass scales. In addition to the cost considerations there are technical parameters that you should take into account. In the previous post I explained which parameters really matter in a DRO setup. Now let’s take a look at some of the commonly available scales and see how they stack up.

Selecting Scales for a DRO - Six Parameters that Matter

Thursday, December 5, 2013Things were easy when iGaging "Remote DRO" were the only scales Android DRO supported. Now that it can work with most of the common scales things are becoming a bit more confusing, judging from the number of emails I've been getting lately. With other things being equal, the choice of scales will have the biggest impact on you DRO's performance. There is a number of options, ranging from cheap Chinese calipers to glass scales and other quadrature encoders. Although I can't definitively answer the question "which scales should I use for my DRO setup", in this post I'll try to explain which parameters matter most in a DRO application.

Android DRO Mini FAQ #2

Saturday, November 30, 2013As the interest in the Android DRO project grows, so does the number of questions I get each day. Some of those questions keep coming up regularly, and since it’s been almost a year since I posted the “Android Digital Readout Micro FAQ”, it’s time to post another one. This post will not cover every question you might have, but hopefully it will address most of the common ones.

Mixed Scale Controller Firmware Posted

Sunday, November 24, 2013Recently I've been working on a new version of a DRO controller that will be able to read a combination of different scales. Although the project is taking much more time than I anticipated, I’m making steady [but slow] progress. Last week I had some free time, so I was finally able to button-up some stability issues with the common “Chinese” scales. Unfortunately I still haven’t finished a truly universal version, so you won’t be able to mix glass and capacitive linear scales (yet). Never the less I posted two versions of the firmware: one that read up to four scales and one that reads the common capacitive linear scales. Links to both versions are posted on the DRO Project Downloads Page.

Finishing the Voltage Shifter for Mixed Scale DRO

Sunday, November 17, 2013A few weeks ago I posted the build instructions for an adapter board that can be used for interfacing various digital scales to the MSP430 Launchpad

Build Instructions for Voltage Shifter Circuit

Sunday, October 13, 2013Last post covered the design considerations for the Voltage Shifter required for the Mixed Scale DRO Controller. As promised, in this post I will provide detailed build instructions for this circuit. The board is designed to work with up to four scales and has three power rails. One provide 3.3V power supply to the comparators and [potentially] iGaging scales; the other two can be set to any voltage between 1V and about 18V. Although the firmware doesn’t [yet] support glass scales or tachometer input, this board is ready for them.

|

| 3"x4" 1200 hole stripboard with a track cutting tool |

Voltage Shifter Circuit for Mixed Scale DRO Controller

Saturday, October 12, 2013Mixed Scale DRO Controller Project Update

|

| Mixed Scale DRO Controller with MSP430 Launchap |

So far the DRO controllers I’ve designed have been able to read only the IGaging (Shahe) Remote DRO scales. Lately I’ve been getting an increasing number of requests for a firmware that could read the standard “chinese” linear scales.A few months ago I started working on a new version that would do just that. Although the project is still a bit rough around the edges, I’m pretty sure that the hardware will stay unchanged and any future updates will be done via firmware. Rather than holding off until the whole shebang is done, I decided to post the stable version of the firmware. In the next few posts I will provide details for the project, design considerations, build instructions and firmware implementation.

How To Upload Firmware to MSP430 Launchpad

Sunday, September 15, 2013A few months ago I posted build instructions for a DRO controller that uses MSP430G2553 microcontroller with a TI MSP430 Value Line Launchpad. Compared to the original version that used Arduino, the Launchpad version has a few advantages, such as lower cost and simpler construction. On the other hand, firmware upload process is not as user-friendly as that offered by the Arduino software. Fortunately, you don't need to install the full-blown IDE, list TI Code Composer Studio or even the MSPGCC tool chain. Instead the pre-compiled firmware can be flashed using a free command line MSP430 Flasher tool offered by Texas Instruments.

Android DRO Application Settings

Friday, August 2, 2013This post refers to the old version of the application. Please refer to TouchDRO Settings Overview for the updated information.

As I mentioned in the last post, the new version of the Android DRO application has a lot of updates. In addition to the new functions there is a plethora of internal changes. Some of the new features are accessible through the “Settings” screen. The good news is that if you intend to use the application with one of the iGaging controllers, the default settings will be sufficient to make it usable out of the box. On the other hand, to take advantage of the new features, you will need to get your hands dirty. In this post I will try to explain what each of the settings does, hopefully making the setup pain-free.

New Version of Android DRO Coming Soon

Wednesday, July 31, 2013When I released last version of the Touch DRO application early this year my plan was to have a new version out by April. This, obviously, hasn’t happened due to a number of reasons, including a busy work schedule, a never ending list of things to do around the house etc. On top of that, from the received feedback, I realized that I had to make the “guts” of the DRO application much more robust before the new features can be added. Now, after a fairly major overhaul, the application is getting ready for the release and includes some of the lacking functions.

This version of the DRO is optimized to be used on a milling machines with three or four linear scales but with a few minor tweaks can be adapted to a lathe. Some functions, such as tool offset, will work identically on a lathe DRO.

Three Ways to Improve iGaging DRO Scales Reliability

Tuesday, July 30, 2013

|

| Shielded USB cables can eliminate most of the noise issues and costs only a few Dollars |

In the last post I covered the root causes of the two most common reliability issues with iGaging digital scales. Although those scales catch a good amount of flack of being unstable when mounted on a machine, the problems are rarely caused by the capacitive transducers. In my experience the problems with random resets and unstable readings can be traced to the wiring and are relatively easy to remedy. The mods described below can be done for under $10 total in less than an hour but can make a huge difference.

Reliability Issues with iGaging Digital Scales

Thursday, July 25, 2013Many people are wary of digital readout setups that use capacitive scales because such setups tend to be sensitive to electrical interferences. A shop full of motors, fluorescent lights, transformers and other equipment is a noisy environment and when that noise gets into the DRO system it can cause havoc with the readout. The most common symptoms of such issues include random resets and floating position readout. While it appears that all “chinese” scales and calipers are somewhat prone to these issues, the majority of the complaints fall on IGaging Remote Digital Readout scales. Surprisingly the scales themselves are rarely the culprit. In my experience 9 out of 10 problems with the iGaging scales can be traced to the wiring and/or the power supply.

AccuRemote vs. iGaging DigiMag Digital Scale Comparison

|

| 12" iGaging AccuRemote next to DigiMag scales |

Recently iGaging has introduced a new Stainless Steel model of their “Remote Readout” digital scales. The new “AccuRemote Digital Readout” scales are supposedly much more accurate and robust than the older DigiMag model, making them a good candidate for a hobby DRO setup. I’ve been getting emails from people wondering if these scales are compatible with the TouchDRO application (or more accurately, TouchDRO Bluetooth Controller), but since I don’t yet own a set, I wasn’t able to confirm this. When a fellow machinistweb.com forum member CaveBob graciously offered to lend his set for a few days, I jumped at the opportunity. Since Bob gave me permission to take one of the scale apart I think it will be helpful to do a side-by-side comparison to see if the scales are really that much better.

Arduino DRO DIY Build Instructions

Friday, July 12, 2013

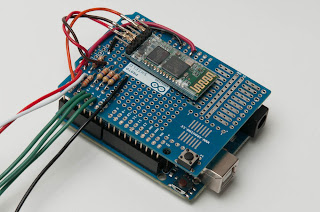

If you’re planning to build a basic digital readout using iGaging “Remote DRO” scales and the “Touch DRO” Android application, you will need to make a controller that will interface the scales to the tablet. At this point I’ve designed two different version: one is based on Texas Instruments MSP430 LaunchPad and the other uses an Arduino. Both controllers offer the same functionality so the choice comes down to a personal preference and the availability of the microcontroller board. Yesterday I posted build instructions for the Launchpad version. In this post I will provide detailed step-by-step directions for a DRO controller using Arduino UNO and an inexpensive Bluetooth adapter.

Build Instructions for MSP430 Launchpad Digital Readout Controller

Thursday, July 11, 2013I’ve been receiving an increasing number of requests to post some build instructions for the digital readout controllers. While working on the step-by-step guide (and building a unit in process) I got sidetracked and ended up designing a controller that can read multiple scales. Even though that project still requires some work I decided to update the basic version of the readout controller to be pin-compatible with the new version.

In this post I will concentrate on the MSP430 Launchpad DRO controller that can read up to four iGaging scales using the middle-of-the-road build described in the Parts List for MSP430 Digital Readout post.

Harbor Freight Caliper Data Format

Friday, July 5, 2013Last week I started putting together the new firmware that will allow the MSP430 Launchpad version of the digital readout to read a mix of different scales and calipers. My last post discussed the needed hardware changes and touched on the high-level requirements. With the adapter board build and tested I was able to start investigating the data formats used by the small collection of calipers I was able to put together. Using my trusty Open Logic Sniffer I was able to identify two different protocols. BG Micro Digital Indicator used the 48 bit protocol described in the excellent article "Chinese Scales" by Shumatech. Surprising none of the other calipers used this protocol.

Mixed Linear Scale DRO with MSP430 Launchpad

Thursday, July 4, 2013An increasing number of readers have been asking me to add support for other encoders to my Digital Readout application, especially the “standard” Chinese scales and cheap calipers. Although I’ve been experimenting with the idea for some time but never got around to getting it done. Last weekend, while working on step-by-step build instructions for the MSP430 Launchpad DRO controller, I realized that I was much closer to the solution than I previously realized. The MSP430G2553 microcontroller that ships with the newer version of the Launchpad kit is a very capable chip that should be able to read three or four different scales with no problems. After digging through my and my father’s garages, and a trip to Harbor Freight I was able to round up six different-looking calipers and a BG Micro “Digital Indicator”, so I was ready to start experimenting.

Troubleshooting Common DRO Connection Problems

Tuesday, July 2, 2013Lately I’ve been getting a fair number of emails and comments from people having various problems connecting the Android application to the Arduino Digital Readout controller. Almost all of them fell into one of three following “buckets”:

- The controller does not appear in the “Select a Device” dialog

- The application is unable to connect to the controller

- The application appears to connect but connection is lost almost immediately

The good news is that those problems are usually easy to resolve, so in this post I will try to address the most common scenarios. The solutions are designed for Arduino UNO board connected via a Linvor HC-0x transceiver (AKA Bluetooth-to-serial adapter) but should work for other combinations as well.

Parts List for MSP430 Digital Readout

Wednesday, June 26, 2013 |

| MSP430 Launchpad requires almost no additional parts |

Tramming Sieg X3 Column and Head

Saturday, March 16, 2013

You might recall that last week I took delivery of a brand new Grizzly G0463 Mill/Drill, also known as Sieg X3 or Sieg Small Mill. Once the mill was thoroughly cleaned, lubricated and put back together it was time to tram the column and the spindle. This step is often missed by new machine owners, but without proper alignment the mill will newer be able to produce accurate work. For instance, if the column is not square, center of the spindle (and thus the cutter) will shift in the horizontal plane as the head is lowered, so the dimensions will be off. On the other hand, when the spindle is at an angle, the holes won't be perpendicular to the table and fly cutters will produce concave surfaces. Fortunately, tramming the X3, although a bit fiddly, isn't very difficult and doesn't require any exotic tools. In fact all you would need is a machinists square, a dial test indicator and a way to hold it [the indicator].

First Impressions from Sieg X3 Mill

Sunday, March 10, 2013 |

| Grizzly G0463 on the shipping pallet |

A few weeks ago, after admitting to myself that I’ve outgrown my little Harbor Freight Mini Mill I decided to sell it [on Craig’s List] and get a larger milling machine. A few hours later, after a number of back and forth text messages it was spoken for and I officially became mill-less. My whole metal shop has to fit along one wall of a two car garage, Bridgeport type milling machines are pretty much out of question. From the get go a friend categorically talked me out of a round column mill/drill, so my choices were limited to Sieg X3, Sieg SX3, a Rung Fu 45 clone or one of the smaller knee mills. After some soul searching I realized that for my projects X3 is the most practical choice. Although pretty small, as far as metal mills are concerned, it still provides somewhat larger work envelope and the design seems to address most, if not all, of my pet peeves with the Mini Mill. On the other hand it’s still light enough to be moved by a few people etc.

After the budget was approved by the accounting department (AKA my wife) I went to Grizzly.com to place an order for a brand-spanking-new G0463. The order was placed late on Sunday, March 3rd and at 8:30 AM on Tuesday (yes, in two day) FedEx called to schedule the delivery. I opted for a “customer pickup” and at noon the same day a friendly FedEx employee was loading it into my truck.

New Version of Android DRO Coming

Monday, February 25, 2013This version of the application has been released quite some time ago. A new version of the Android DRO application is in the works, due to be released on or before August 10, 2013.

It's been more than two months since the initial release of my Android Digital Readout application Touch DRO. The first version was very basic, offering only a few functions commonly found on a digital caliper. After bit over two months of work I'm getting close to releasing a new version. The new version has a number of bug fixes and improvements, as well as some long overdue features, such as point memory, position preset and the so-called 1/2 function.

Jet Lathe Wet Apron Conversion

Wednesday, February 20, 2013Last week I posted my progress cleaning the apron on my “new” Jet 1024P lathe. As I said, I am very pleased with the overall condition and build quality. As I was putting the apron back together I realized that there are no provisions to oil the insides once it's coupled with the saddle. The only way to get any lubricant into the apron is through the opening around the cross slide screw, but it is normally covered with a piece of sheep metal bolted to the saddle. Getting to it isn't very convenient, but even once the cover is removed only some of the gears are accessible.

Cleaning Up Jet 1024P's Apron

Saturday, February 16, 2013 |

| You won't believe it, but there is an apron under all this gunk. |

When I purchased my Jet 1024P lathe a few weeks ago I pretty much knew that I will spend hours and hours bringing it back to a serviceable condition. Although the important parts of the lathe appeared to be in good condition, there was something loose in the apron. Engaging one of the power feeds made horrible grinding noise. It didn't feel like a broken gear or a missing tooth, so my guess was a loose key or something similar. Before spending time on anything else, I decided to dig into the apron. Taking it off the lathe didn't take much effort: after removing the lead screw, I had to loosen two hex screws on the top and the apron readily disconnected from the rest of the carriage assembly.

Jet 1024P - Construction and Build

Friday, February 1, 2013You might remember from my last post that I’ve acquired an old Jet 1024P metal lathe. The machine is solid but appears to be poorly [if at all] maintained and extremely dirty. In process of removing what looks like three decades worth of chips and grease, I was finally able to closely inspect the lathe, and even run the spindle for a few minutes. I will reserve the final judgement on the condition and quality until the overhaul is done. On the other hand, I have a good idea of the features and the construction. Since I’m upgrading from a 920 lathe, this will be somewhat of a side-by-side comparison of features that I’ve found to be important for my particular needs.

My New 30-year Old Jet 1024 Lathe

Monday, January 28, 2013 |

| Late '70s Jet 1024P Lathe |

This weekend I picked up an old (presumably late '70s) Jet 1024P lathe. Surprisingly, there is little or no info on the internet about this machine. I suspect I'm not the only one having trouble finding the information, therefore, as I'm working through the lathe, I will be posting detailed write-ups and pictures.

Gumdrop Case to Make Galaxy Tab Garage-Worthy

Wednesday, January 9, 2013 |

| 7" Galaxy Tab 2 in Gumdrop Protective Case |