It's been a while since the last TouchDRO V3 status update, so it's a good time for one. Over the last few months, I had a chance to spend a good amount of time working on the application and have made a lot of progress. The application is now in a state where I can use it on a milling machine and not feel that I'm testing some unfinished beta version; lathe functionality is still a bit behind and will be my main focus next.

The work that I've completed since the last update includes several major improvements to the inner workings of the application, a lot of minor bug fixes, performance improvements, and overall "polish". Some of the more notable items are:

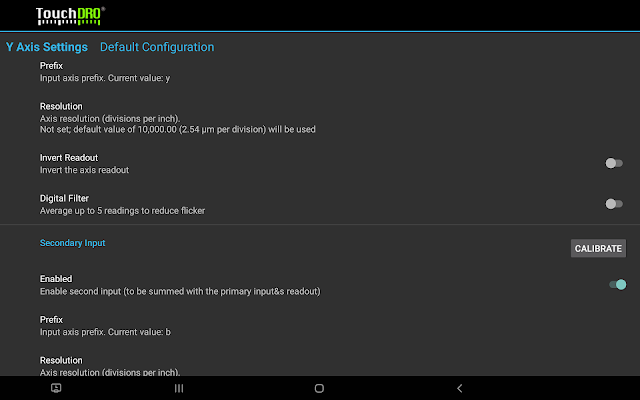

- A major overhaul of the way the application handles Configuratoins (formerly called "Preference Banks")

- Better organized application settings, split into logical sections

- Scale calibration wizard

- More configurable user interface

- Improved support for combination machines

The complete list of changes is pretty long (and mostly boring), so in this post I will briefly cover a few of the more noteworthy changes.

Better Combo Machine Support

Traditional DROs come with two-to-four axis inputs that are hard wired to the corresponding readouts with more sophisticated units offering the ability to sum up to two axes. Current [old] version of TouchDRO follows the same scheme, where x,y,and z inputs are mapped to the X, Y, and Z readouts respectively; W input can be displayed as a separator angular readout or be summed up with one of the other three readouts.

This approach is not ideal for machines that have multiple spindles such as mill/lathe combos or vertical/horizontal mills. You might recall that by convention, the axis that is parallel to the spindle's axis or rotation is Z and the other two are determined using the "Right Hand" rule. In other words, the coordinate system of the machine changes, depending on which spindle is used. For instance, when the lathe spindle is used, the machine's bed is Z and cross slide is X; when milling spindle is used, the bed and cross slide become X and Y respectively. Furthermore, a lathe and a mill use completely different tooling, DRO functions and workflows. Since most combo machine owners don't own a lathe-specific and mill-specific digital readout, they have to compromise and deal with various idiosyncrasies when using different machine functions.

|

| X, Y, and Z readouts can be set to sum up any two arbitrary scale positions |

To accommodate combination machines, I've made a number of changes to the application. First of all, I've made managing and switching between configurations much easier. List of saved configurations [formerly called "Preference Banks"] is accessible from the main application menu, so switching between them takes a swipe and two clicks. Each configuration is treated as a separate instance of TouchDRO and has its own state, settings, tool library, and saved sub-datum memory. During the switch, TouchDRO saves things like selected sub-datum, tool offsets, units, mode, etc. with each configuration, so they can be re-called when the configuration is reloaded. Furthermore, to handle coordinate system changes, TouchDRO now allows mapping of any input to any readout. Each of the three linear axes (X,Y, and Z) can be mapped to one or two [summed] inputs, and the angular axis can be mapped to a single input.

Using these features, each function of a combo machine can have a separate configuration with separate tool library, saved workspaces and settings. Since the scales can be mapped to the correct readouts, the coordinate system for each machine will be correct and the DRO functionality will behave as expected. In essence, TouchDRO will behave like two separate digital readout units.

Axis Resolution Calibration

After installation, a DRO has to be properly calibrated to ensure maximum accuracy. This is less obvious with traditional [inexpensive] DRO units, since they are usually preset to the scale's nominal resolution and the small errors are hard to notice. With TouchDRO, the calibration is much more important, since the system can be used with many different scale types and can't be preset to a standard resolution out of the box. The process is very simple conceptually, but many users, especially in the countries that use the Metric system, had trouble with it.

In the new version, I've added a calibration wizard that will guide the new users through the calibration process for each axis input. The process consists of entering the dimension of the calibration block and locating the edges using an edge finder or some other device. The application will do the necessary math, determine if the scale readout needs to be inverted and prompt the user to accept or reject the calibration data.

|

| The calibration wizard calculates axis resolution |

Start-to-finish it should take less than five minutes per axis. Notably, calibration can be done using either Metric or Imperial systems, so it's no longer required to deal with Millimeter-to-Inch conversion, etc. Furthermore, the settings screen shows axis resolution as encoder divisions per inch, and microns per division.

Main Display Layout Configuration

Following the theme of making TouchDRO more flexible, I've made the main readout screen more configurable. Besides a number of tweaks that will make TouchDRO work better with various tablet sizes, there are several major improvements. As I mentioned in some earlier posts, I've completely redone the main screen layout. First of all, I've made the right panel collapsible, so the saved sub datum list can be hidden when not in use. This freed up screen space for two additional axis action buttons next to each axis readout and more function buttons. Furthermore, the function buttons are now configurable, so you can choose which ones are shown.

|

| Each axis readout now has three fully configurable buttons |

|

| The number and functoin of axis action buttons is configurable |

Based on the feedback from a few fellow forum members, I've made the buttons fully configurable. You will now be able to select what function each of the tree buttons performs, and whether it will be shown when the right panel is expanded and collapsed. Since the buttons are configured for each axis individually, you will be able to tweak the display to work best for your particular work style. For instance, it will be possible to set X and Y to show "Set Zero", "Center" and "Audible Warning" buttons, and Z to show "Set Zero", "Absolute/Incremental" and "Swap Tool" functions. Similarly, on a wide aspect ratio screen there might be enough space to show all three buttons even when the panel is expanded, while on a 3:4 aspect ratio screen only two buttons will fit with the panel collapsed.

|

| TouchDRO now supports vertical mode |

Last, but not least, the application now supports "portrait" orientation that offers a split screen view. On a larger tablet you will now be able to display the main DRO screen and the graphical view at the same time, which will make working with saved sub-datums much more convenient.

Conclusion

The work I've completed over the last few months ended up following the theme of making the application more flexible and configurable. TouchDRO's customer base is very diverse, and my goal for TouchDRO is to offer a digital readout that adapts to your needs and preferences, and not the other way around. Things like better combo machine support will provide combo machine owners with a DRO that doesn't require a compromise when switching between machine spindles, so they will be able to use both machine functions to their fullest potential. The intuitive calibration wizard will definitely make initial setup easier and more accurate. Finally, I hope that the enhancements that I've made to the main DRO screen will make the application even more intuitive and convenient.

I have recently taken the plunge and purchased your version 2 adapter for glass scales (unassembled 4 axis kit). I also purchased 3 Ditron glass scales from China. So far I have been very pleased with the experience. Your adapter arrived quite promptly. The PC board layout looks very professional. My Ditron scales arrived in about three weeks and they look good as well. I deeply appreciate your detailed instructions for reverse engineering the pinouts on the scales since the included manual is in Chinese. Once I have finished verifying the pinouts I will be soldering the connectors and then testing the system. Assuming that goes well, I will be installing the unit in an enclosure and then mounting the scales on my Jet mill. I have your app running on a 10 inch Lenovo tablet. I'm quite impressed with the UI. Nicely and thoughtfully designed. So far everything looks great. I may post some updates as things progress.

ReplyDeleteThanks for making this possible.

Dave Fedukowski

I just uploaded my video to youtube. It was on imgur for a year with 19K view.

ReplyDeleteSo hope you get some more orders with the youtube video. It shows me cutting a part using the data saved in the workspace. Makes it easy to make repeat parts as well as blind cuts on a manual lathe.

Any word on adding the compound feature? This will let you use W axis output as input into X and Z axis readouts. (X_in * sin(W_out) or something similar)